| After stripping. appropriate contacts or wire

end ferrules can be crimped to the end of the cable. Crimping produces a

reliable connection between conductor and contact, and has more or less

completely replaced soldering. Crimping describes the production of a uniform,

nondetachable connection betweem conductor and connecting element. This should

be achieved exclusively by the use of a high-quality precision tool. The result

is a safe, reliable connection in both electrical and mechanical terms. |

|

| |

|

| Weidmuller offers a wide product

range of mechanical crimping tools. An integral ratchet mechanism with

disengaging option guarantees optimum processing quality. Crimp connections

produced with Weidmuller tools comply with international standards and

specifications. |

| |

|

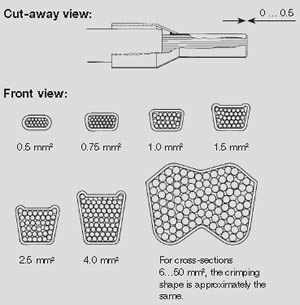

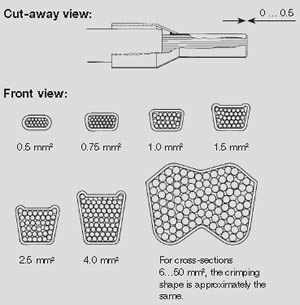

| Crimping of wire end

ferrule: Optimum crimp of different cross-sections as an example: |

Examples for the visual

inspection of a crimp connection with manual and automatic crimping tools by

Weidmuller: The conductor insulation must be pushed into the plastic collar.

The ferrule sleeve must be completely filled by the conductor. Depending on the

cross section, the conductor should protrude approx. 0...0.5 mm from the

ferrule sleeve. |

| |

|

| |

| Faulty

crimping connections due to incorrect combination of cable and wire end

ferrule: |

| |

| It is not possible for

a tool to function reliably with every combination of conductor and crimping

material. It is possible that the stranded requirements for the crimped product

can't be achieved, although taken on their own, both conductor and crimping

material comply with the corresponding standard. The individual production

tolerances of conductor and crimping material do not allow every conductor to

be combined with every contact. |

| |

| The combination of

conductors, crimping material and crimping tool must be coordinated: this

procedure is all the more difficult given the large number of products on the

market. This means that the material must be defined and the crimping result

tested, ensuring that the test, and later on the tool, satisfy the same

conditions. |

| |

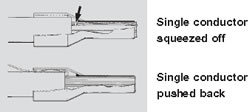

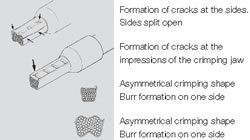

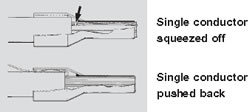

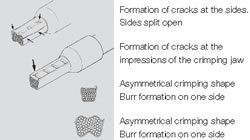

| Faults which can occur

during crimping: |

|

- Cracks along the sides and die impressions

- Splitting of the ferrules

- Asymmetrical crimping shape

- Extreme burrs formed along the sides

- Ferrule not filled by the conductor

- Single conductors pushed back protruding from the

collar

- Single conductors squeezed off

- Plastic collar damaged by the crimping jaw

- Conductor insulation not pushed into the plastic

collar

- Ferrule bent longitudinally after crimping

|

| |

|

|

| |